Innovative

Informative

Comprehensive

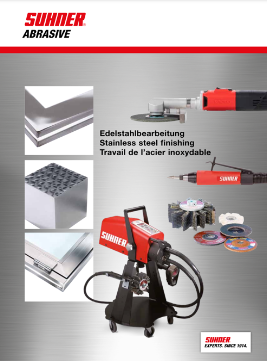

Stainless Steel Processing: Your Solution for Perfection and Precision

Stainless steel processing requires the highest precision and excellent tools. At SUHNER, we offer optimal solutions for your specific requirements in stainless steel processing. Our extensive product range is designed to help you with every challenge, whether it's grinding, polishing, or surface treatment. With our innovative tools and high-quality abrasives for stainless steel processing, we ensure that you always achieve the best results. In our knowledge PDF, you will find detailed information about our tools and specialized methods.

Ensure top quality in stainless steel processing

Our products for stainless steel processing are characterized by their high robustness and durability. Every processing comes with individual requirements, which is why we offer a wide range of tools and machines specifically developed for stainless steel processing. Our solutions are ideal for processing stainless steel in various shapes and sizes, always ensuring a flawless surface.

Gentle Surface Processing – Challenges and Solutions

A crucial aspect of stainless steel processing is surface treatment. The high demands of the sheet metal processing industry have led manufacturers of non-rusting fine sheets to produce their semi-finished products with such high surface quality that often no rework is needed on the end product – only a final finish. Therefore, it is important to treat these sheets as gently as possible during further processing, as surface reworking through grinding and polishing is expensive and labor-intensive. Surface processing can be performed on equipment typically used for other metallic materials. However, the following physical properties of stainless steels must be taken into account:

- Higher Strength:

This can affect the removal rate and is associated with higher wear resistance in martensitic steels.

- Lower Thermal Conductivity in Austenitic Materials:

This can lead to heat build-up and distortions on the sheet surface with higher contact pressure or grinding speeds.

- Greater Thermal Expansion Coefficient in Austenitic Steels:

This is about 40% greater compared to ferritic steels and must be considered during processing.

It is essential to use special grinding and polishing agents for stainless steels. Also, tools used for processing stainless steels should only be used for these steels, as using them on unalloyed steels before processing stainless steels can lead to contamination and foreign rust formation. Therefore, it is advisable to separate work on un- or low-alloyed steels from grinding or polishing work on stainless steels.

Different Types of Steel and Their Applications

Refinement of Grinding through Brushing

Cleaning, grinding, and smoothing welds

Special tools for specific applications

SUHNER: Tradition and Quality

Since 1914, SUHNER has been your expert in the development, design, and production of machines and tools for efficient surface processing. Through intensive research and development, high-quality standards, and close collaboration with users, we create customized solutions for the challenges of industrial everyday life. With state-of-the-art production facilities in several countries and a global sales network, we are now a leader in surface processing. Our comprehensive range of products and expertise guarantees you always the best tools and machines for your needs. Invest in the quality and reliability of SUHNER and optimize your production processes. Discover our range and experience the benefits of our products in stainless steel processing. To make your work easier, we have worked with our customers to develop various solutions for common processing tasks. Download our knowledge PDF now for more details. Contact us now, take advantage of our special services, and get professional advice!

Questions? Please contact us:

Follow us on