Innovative

Educational

Comprehensive

Professional Surface finishing for Metal

The surface treatment of metal is an essential process in many industries. It is the key to a flawless and functional surface. With our advanced processes and high-quality abrasives, we offer you the best solutions for processing your metal workpieces. Our technologies enable you to carry out even the most demanding projects with the highest precision and efficiency. Find more information in our knowledge PDF about our tools and special methods.

Versatile Methods for Surface finishing

At SUHNER, we offer a wide range of methods for surface treatment. Our technologies ensure that every component is optimally processed. We rely on various methods to ensure that your workpieces meet the highest standards:

- Grinding: With precise grinding methods, we achieve perfect surfaces and remove unwanted materials. Whether rough or fine grinding, our machines and abrasives are designed to give you the best possible control and quality.

- Deburring: This step ensures that all edges are clean and safe. Sharp edges and burrs can affect the functionality and safety of your components. Our deburring processes remove these efficiently and reliably.

- Polishing: For a shiny and smooth finish that highlights your products. Polished surfaces not only improve appearance but also enhance corrosion resistance and the lifespan of your components.

- Coating: Protection and refinement of your surfaces for longer durability and better performance. Various coating methods provide additional protection against wear, corrosion, and other environmental influences.

Each of these processes is carefully tailored to your specific requirements to achieve the best possible result. Our experts work closely with you to develop the best solutions for your individual needs.

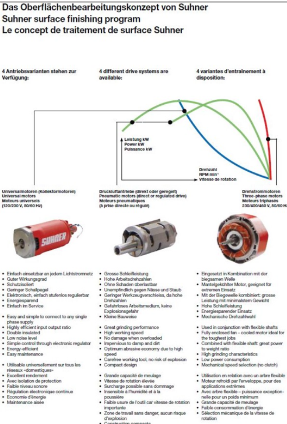

Drive Variants

To ensure efficient and precise surface treatment of metal, we offer a variety of powerful drive variants. Our range of drives allows you to always find the right solution for your specific applications and achieve a perfect surface finish:

- Universal Motors (Commutator Motors): These motors are versatile and offer high performance in a compact size. They are ideal for applications that require flexibility and mobility and are excellent for polishing and other fine processing of components.

- Pneumatic Drives: These drives, whether direct or regulated, are characterized by their high reliability and durability. They are particularly suitable for environments where electric drives are not ideal and provide powerful support for surface treatment and grinding.

- Three-Phase Motors: These motors offer a constant and powerful drive solution for continuous operational requirements. They are optimal for heavy industrial applications that require high stability and efficiency, especially when processing large components and using high-performance abrasives.

By choosing the right drive variant, you can significantly increase the productivity and quality of your surface treatment processes. Our products are designed to meet your specific needs and maximize the efficiency of your surface treatment. Let our experts advise you on which drive solution best suits your requirements to achieve optimal results in processing and surface treatment of your metal workpieces.

High-Quality Abrasives and Grinding Equipment

Our abrasives and grinding equipment are specially developed for metal processing. They enable precise work and contribute to a perfect surface finish. Our products are durable, efficient, and easy to handle, making them ideal for industrial use. Whether it's grinding belts, grinding discs, or special polishing agents, we offer you the best tools for your applications.

Our Abrasives at a Glance

- Grinding Belts: For even grinding and high removal rates. Our grinding belts are available in various grits and offer you the flexibility you need for different applications.

- Grinding Discs: Ideal for rough and fine grinding as needed. They are robust and durable, making them an economical choice for your workshop.

- Polishing Agents: For a mirror-smooth surface. These agents are specially formulated to achieve the best finish and maximize the surface quality of your components.

- Deburring Tools: To safely and efficiently remove sharp edges. Our tools are designed to be easy to handle and help you work quickly and effectively.

These abrasives are designed to make your work easier and maximize the quality of your components. With our wide range of products, you will always find the right tool for your specific requirements.

Quality and Precision from SUHNER

Surface treatment of metal requires the highest precision and quality awareness. At SUHNER, we rely on the latest technologies and years of experience to offer you the best results. Our goal is to exceed your expectations and help you produce high-quality products. Our comprehensive quality controls and innovative processing techniques guarantee that your components always meet the highest standards.

The Advantages of Our Surface Treatment:

- Precision: Every process is carried out with the highest accuracy. Our machines and tools are designed to perfect even the smallest details.

- Quality: We only use the best materials and the latest techniques. This ensures that your components not only look good but are also durable and robust.

- Efficiency: Fast and effective processes that optimize your production. Our methods are designed to shorten your production time and reduce your operating costs.

With our expertise in surface treatment, we guarantee you always the best tools and machines for your requirements. Download our knowledge PDF for more details. Contact us now, use SUHNER's special service, and get professional advice!

Questions? Please contact us:

Follow us on