Contact us now!

Suhner Industrial Products LLC.

25 Anderson Rd - Plant 2

Rome, GA 30161

abrasive.us@suhner.com

+1 706 235 8046

Suhner Industrial Products LLC.

25 Anderson Rd - Plant 2

Rome, GA 30161

abrasive.us@suhner.com

+1 706 235 8046

Suhner Pty Ltd.

6/81-83 Station Road

Seven Hills NSW 2147

abrasive.au@suhner.com

+61 (0)2 96 48 58 88

Suhner India Pvt. Ltd.

Plot no. 50C2 & 50D Bommasandra Industrial Area

Bangalore- 560099

abrasive.in@suhner.com

+91 (0)80 27 831 108

Get professional and free insights into foundry with the foundry pocket guide!

Battery series

Unlimited mobility when processing your metal workpiece

Modern, brushless motor

Cordless power packs

Reliable tools

The latest generation of cordless tools from SUHNER marks a turning point in terms of performance and efficiency in the metalworking industry. Experience unlimited mobility when working on your metal workpieces, supported by the impressive power of our cordless series. This innovation benefits from an ultra-modern, brushless motor, which guarantees consistently high torque and thus sets new standards. The cordless tools from SUHNER set new standards!

Discover now

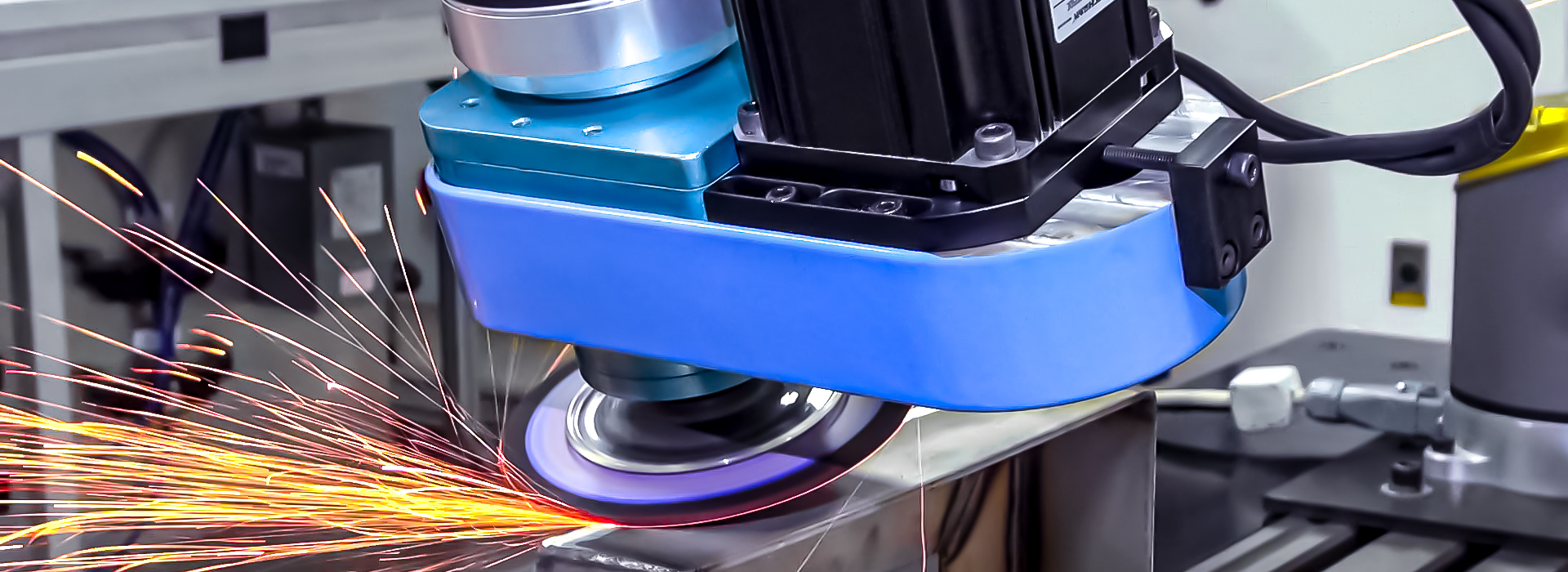

ROTOmax 4.2 Twin

Shortened process times, minimised errors, regular grinding pattern and universal use - the ROTOmax 4.2 TWIN offers all this and much more.

Process reliability

The right handpiece for every application

Increased surface quality

This flexible shaft machine is suitable for processing and finishing the surface of metal workpieces in multi-shift operation. In particular, it supports manufacturers of machines and apparatus for food and pharmaceuticals as well as companies for kitchen construction. Whether for grinding, polishing, deburring or cutting, the modular and powerful drive unit is versatile.

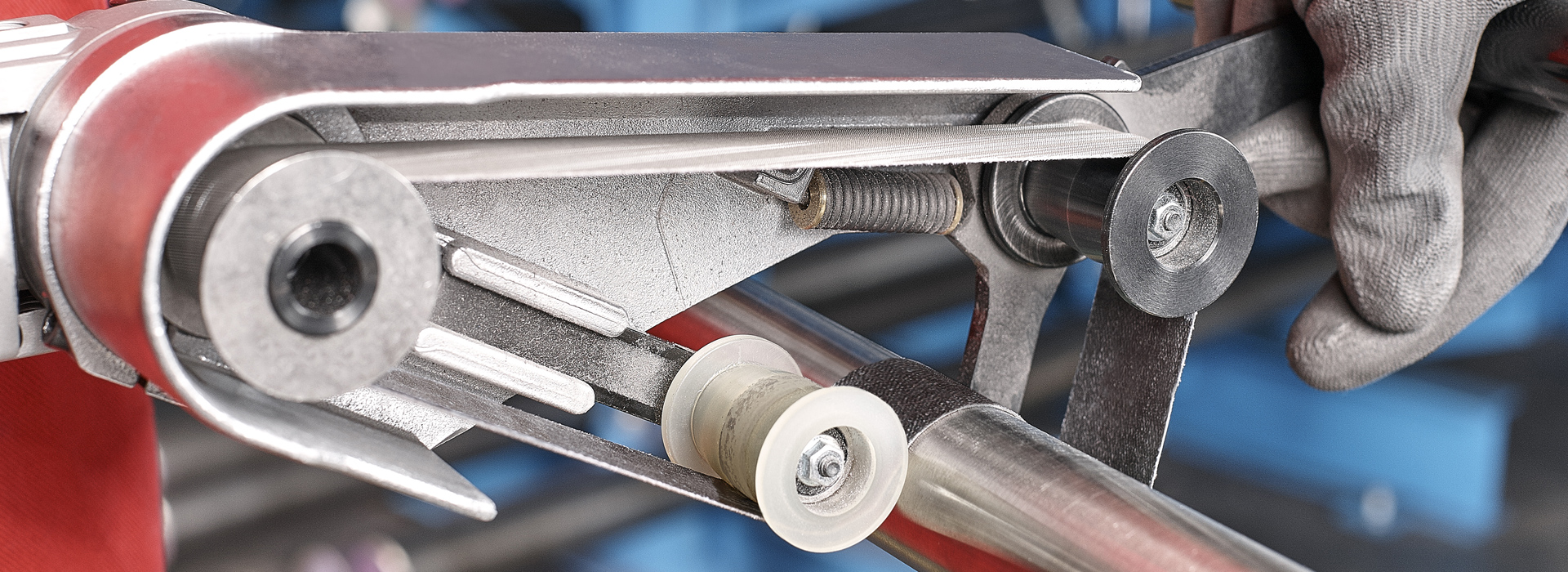

BRUSHmax 3.0

Clean, polish and passivate stainless steel weld seams in just one operation!

24h/7 use thanks to inverter technology

Quick and easy

Safe for the environment

The BRUSHmax 3.0 is a safe and effective tool for cleaning stainless steel surfaces, especially after welding. It quickly and easily removes the blue and brown iron oxide stains without changing the surface texture of the metal.

In addition, the BRUSHmax 3.0 passivates the metal in the same operation, so that the fully desired result is achieved even faster. The liquids with which the BRUSHmax works only become reactive at high temperatures. Under normal conditions, they are therefore comparatively harmless to the user and the environment.

In order to get the desired or requested grinding result the combination of abrasives, machine and the process is crucial. Our «SUHNER Manual for cost-optimized grinding processes» is supporting you in doing so.

For us the parameters of cost savings, improvement of the processes and achieving the required surface finish are crucial. Thanks to the wide Suhner ABRASIVE range of air power, electric power, battery power and flexible shaft driven machines, there are no limitations regarding the selection of the right abrasives and grinding processes with the opportunity to set the precise grinding speed.

Suhner supports you in cost and process improvement.

Product and Application Counselling

Benefit from our free of charge  concept offered by our technical sales engineers.

concept offered by our technical sales engineers.

Suhner ABRASIVE is characterized by the fact that we can find the best solution with our customers thanks to our ![]() concept. Our vehicles are equipped with most of the available machines and a wide selection of high quality abrasives. Thus, different machines and abrasives can be tested on any application to result in the best solution.

concept. Our vehicles are equipped with most of the available machines and a wide selection of high quality abrasives. Thus, different machines and abrasives can be tested on any application to result in the best solution.

In addition to solving the problem, our customers can test the grinding machines and experience our quality.

Our sales Engineers are experts in this field and can advise you not only during the decision-making process but throughout the project life cycle.

Suhner ABRASIVE Newsletter

Stay informed!

Subscribe to the newsletter now and don't miss any news.

Follow us on